Know-how

Decades of experience in material and spring characteristics.

Springs seem to be simple components at first glance. However, the function of a component or even a complete device often depends on their trouble-free performance. They are to store energy, isolate vibration, apply force, reduce impact force, carry loads or control movements and thus are essential parts in vehicles, mechanical and electrical devices, medical and computer technology and much more.

Finding the appropriate spring for the intended use isn’t always as easy as it seems. We support you with:

- In-depth experience in spring materials

- Comprehensive knowledge of technical springs as regards thermal and power specific properties

- Technical drawings

- Feasibility checks

- Tool making for prototyping

- Qualified staff

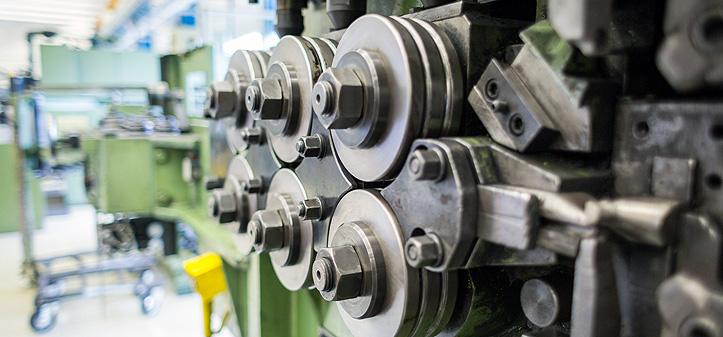

- High-tech machinery

This guarantees an optimum ratio of form, function and costs.

Custom springs

We customize springs according to your drawings or samples and are specialized in minimum tolerances and tight spring index. The latter is gaining importance, since technical devices are increasingly built in more compact forms.

In order to continuously develop springs we do research in collaboration with technical universities and various committees of the Association of German Spring Industry (VDFI). This is an excerpt of our research projects:

- Influence of end and transition coils on function and performance of cold formed compression springs

- Determination of functionally relevant and production related spring wire parameters (modulus E and G)

- Tensile strength of helical compression springs as regards extremely high stress cycles

- Determination of fatigue strength and relaxation diagrams for highly stressed compression springs

- Participation in the subcommittee "Quality Management" of VDFI

- Leadership of the working group "Measurement and Testing" of VDFI